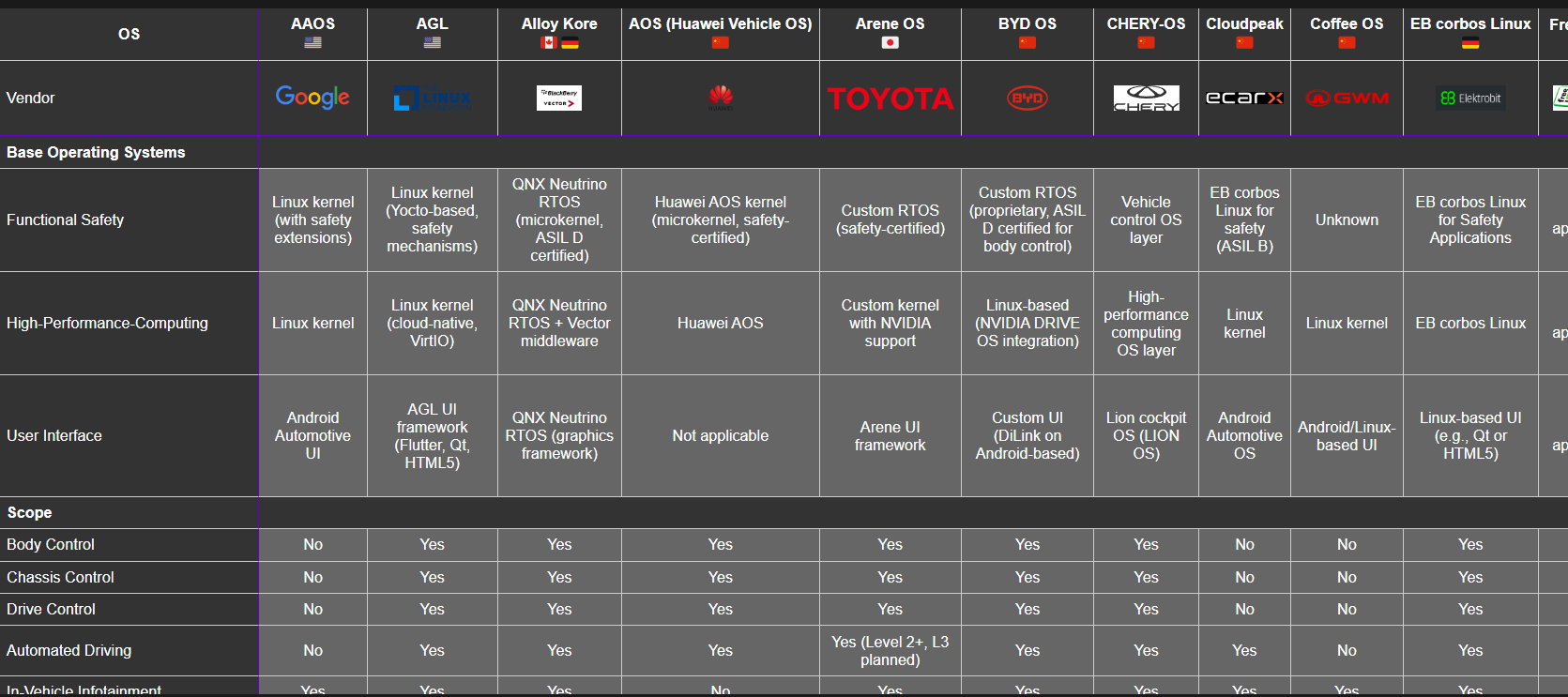

🚀 Automotive Operating System Comparison updated to version Q1/2026 🚀

Key enhancements from version Q3/2025:

✅ Detailed #OTA comparison

✅ Breakdown of Base OS in #FuSa, #HPC and #UI

✅ More conservative rating, if or if not a feature is fulfilled

✅ Change from Grok to DeepSeek AI as main #LLM for better accessibility of 🇨🇳 pages

✅ Added #Eclipse S-Core, Veecle-OS, #SafeRTOS and #RedHat #IVOS.

Tag: SDV

-

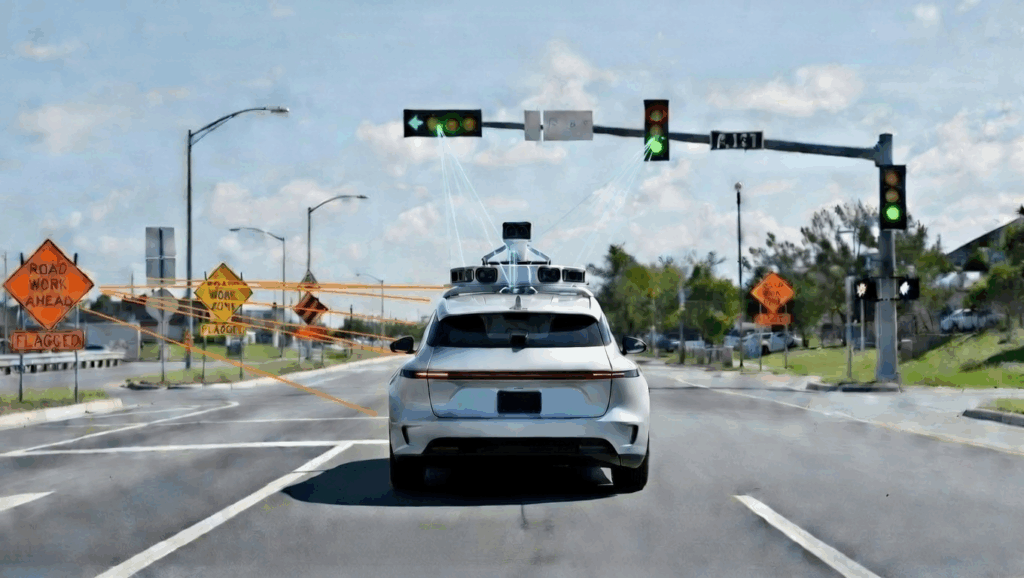

Towards Truly Viable Autonomy

Ten years after unveiling the groundbreaking CHAD prototype at CES 2016, the dream of fully autonomous driving feels closer than ever – yet a fundamental conflict persists: systems must still choose between natural, human-like driving behavior and verifiable safety without self-caused accidents. In this new article, Benedikt Schonlau reflects on a decade of progress and reveals the three foundational enablers that will finally cut this Gordian knot:

- Functionally safe by-wire chassis

- Targeted V2X infrastructure at critical points

- Reliable connectivity with selective remote support

Discover why these elements are essential to deliver comfortable, confident autonomy that earns real-world trust – without compromise. Read the full article: Towards Truly Viable Autonomy

#AutonomousDriving #V2X #FunctionalSafety #SDV #viableworks

-

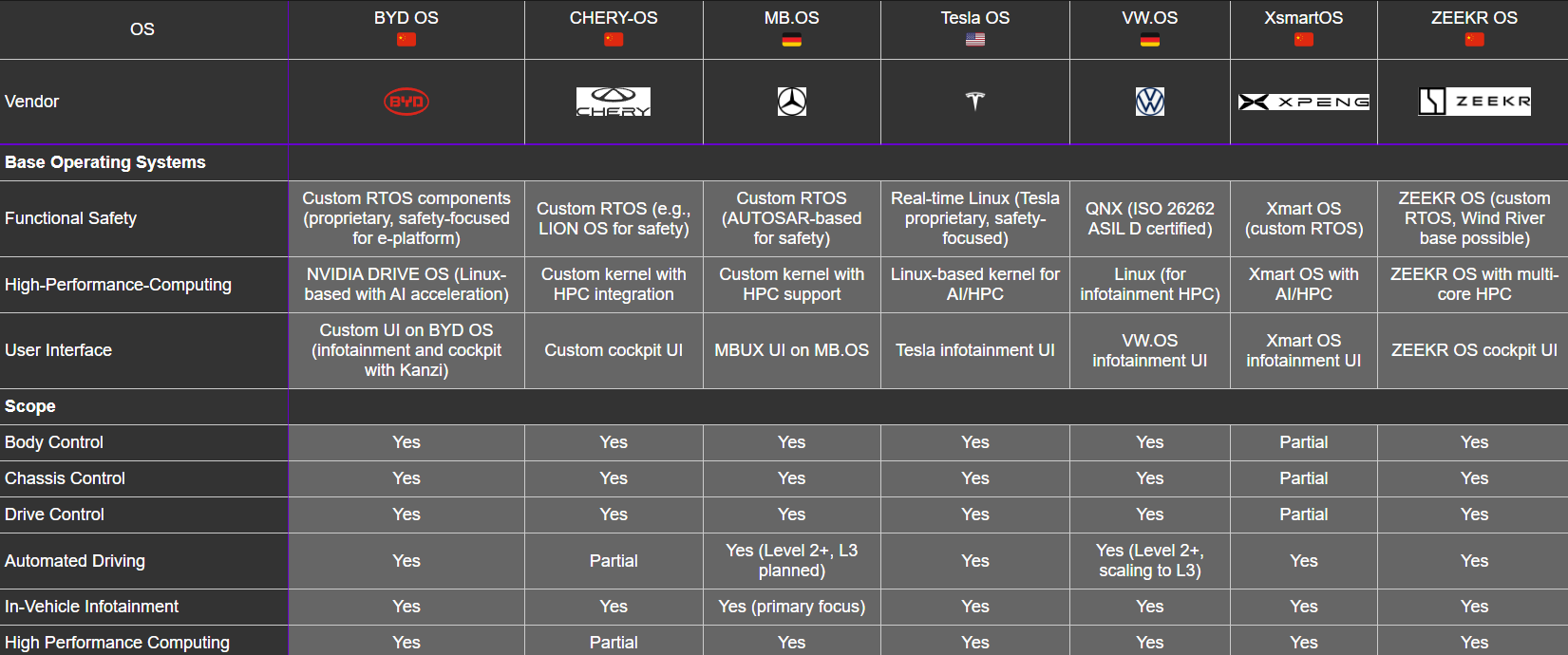

Update: Automotive OS Comparison

🚗 Exciting Update: Automotive OS Comparison Now Interactive and Packed with Q3/2025 Insights! 🚀

Fellow automotive innovators, we’ve leveled up our overview of vehicle operating systems! The new version transforms it into a dynamic, customizable comparison tool tailored for your automotive projects.

🔍 What’s New in This Update?

✅ Interactive Comparison Table: Dive deep into top OS like BlackBerry QNX, Google Android Automotive, Toyota Arene OS, and more – now with easy show/hide columns for a personalized view.

✅ Expanded Details: New columns covering scope (e.g., infotainment, ADAS), supported chip cores (ARM, x86, RISC-V), key features (hypervisor support, ASIL D safety), middleware (SOME/IP, DDS, MQTT), connectivity (Bluetooth, Ethernet, CAN), and fresh 2025 release info.

✅ Enhanced Usability: Tooltips for vendor details, “Show All/Hide All” buttons, and hover effects to streamline your evaluation.

✅ Updated Data: Sourced from official vendor docs and industry reports as of September 17, 2025 – ensuring reliable Q3/2025 insights!

This upgrade empowers engineers, developers, and OEM teams to make informed choices for software-defined vehicles faster than ever. Spot any gaps or updates? Email info@viable.works – your input keeps it cutting-edge!

Explore the revamped guide: https://viable.works/content/automotive_os_comparison/index.html

#AutomotiveTech #OperatingSystems #EmbeddedSystems #ADAS #AutonomousDriving #SoftwareDefinedVehicles #AutoInnovation -

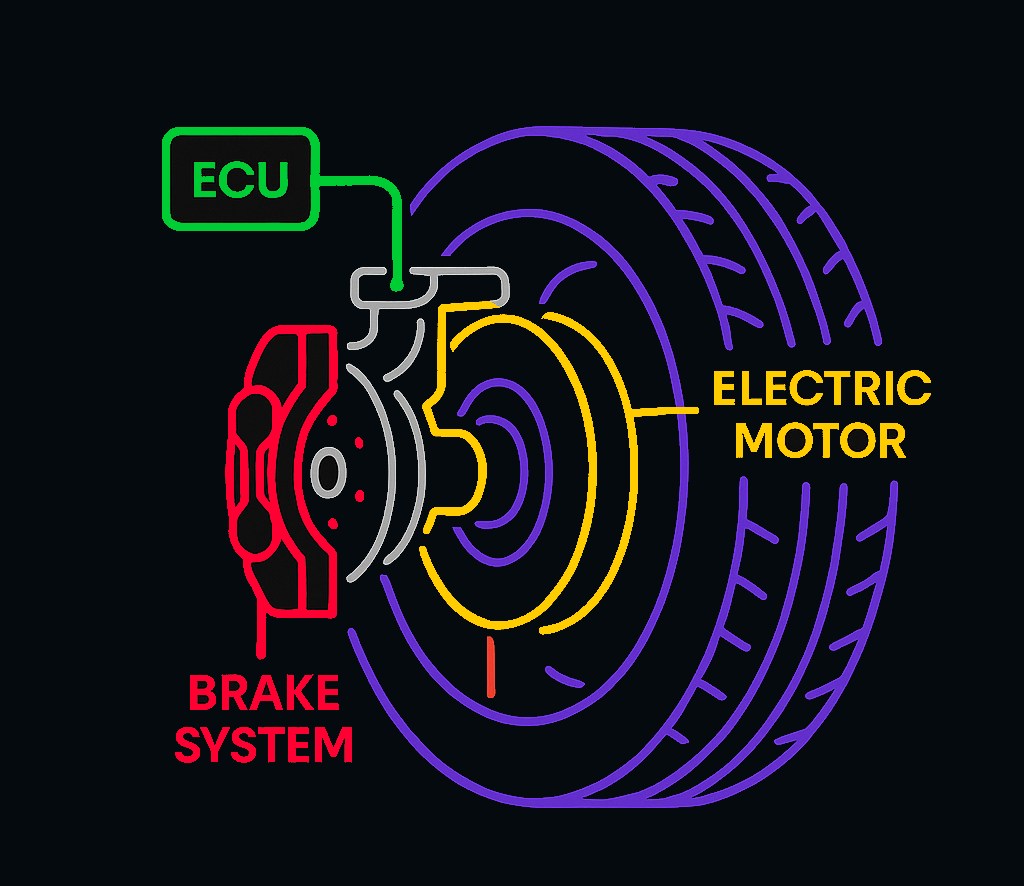

Understanding Zonal Architecture in Modern Vehicles

Zonal architecture is revolutionizing how modern cars are built, replacing messy wiring with smart, organized systems. But ask ten engineers what it means, and you’ll get ten different answers. Let’s clear up the confusion and explore why this design is the future of vehicles!

How it began?

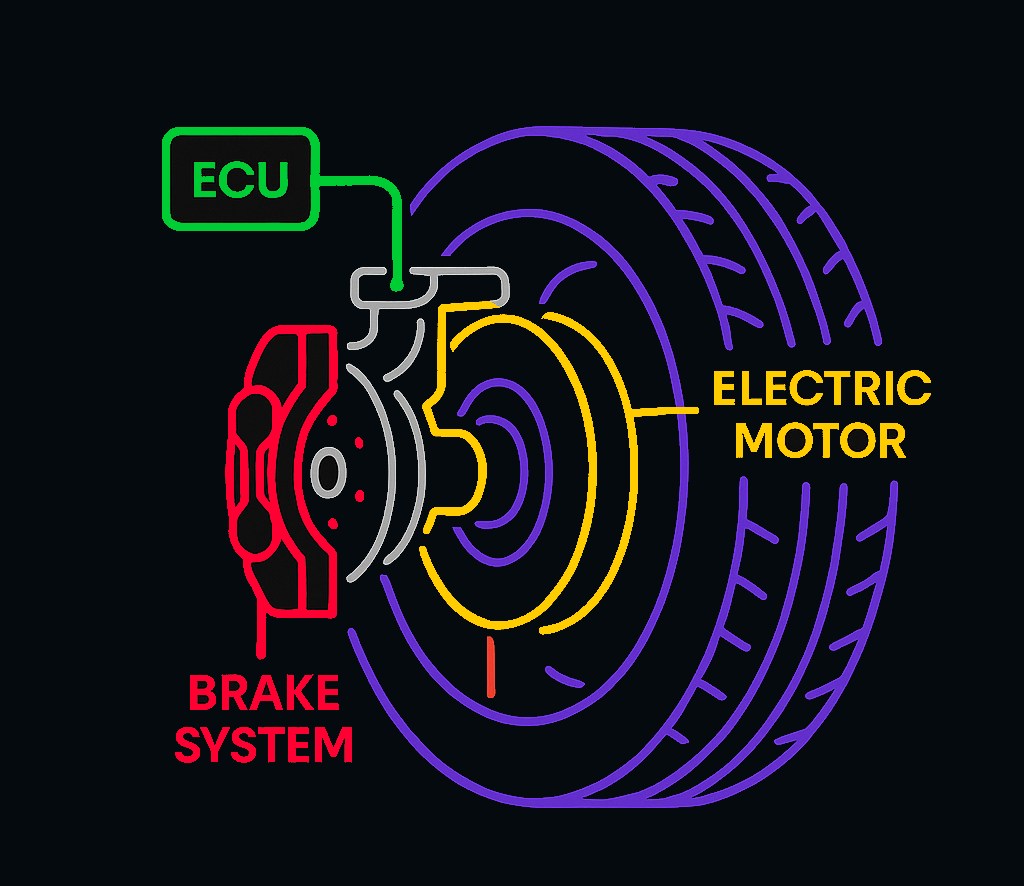

Vehicle wheel with integrated Electric Motor, Brake and ECU The first ideas of the zone concept were pitched by Siemens, when they worked on their project e-Corner – A modular vehicle dynamics concept that integrated a separate motor, brake and ECU into each wheel.

This project highlights the massive advantages of the zonal concept:

- The vehicle body is freed up from technology and components.

- Less material usage due to the application of torque, where it is needed.

- Better maneuverability due to the mechanical decoupling of the car.

Why did it fail?

But if this concept is so beneficial, why don’t we see it now in all modern vehicles?

The simple answer to that: It is difficult to make it safe. A mechanical form-fitting connection of the wheels cannot be hacked and doesn’t change its behavior due the loss of electric power. But with this concept, all of that can happen.

When each ECU acts individually, the vehicle motion can get out of sync and endanger the vehicle. Therefore, domain ECUs for the engine, the braking- and steering-systems will survive even in the most modern vehicle architectures.

Why is that important for Zonal Architectures?

The Siemens e-Corner case exploits the limitations of a zonal architecture. A full zonal-architecture doesn’t have a good price-value-ratio. Therefore, it is not done and we will even in the midterm future have dedicated domain controllers that are not integrated into the zones.

Another decisive factor is the cost for bandwidth. While the body, chassis and powertrain domain only slowly demand more bandwidth, ADAS and Automated Driving on the one hand and In-Vehicle-Infotainment including all connected services on the other hand continuously demand more bandwidth.

Putting those domain functions together in a zonal concept with the other domains would make these domains more expensive, because they have to switch from LIN, CAN and CAN-FD to 10BASE-T1S Automotive Ethernet or even higher Automotive Ethernet speeds.

How will the E/E-Architecture finally look like?

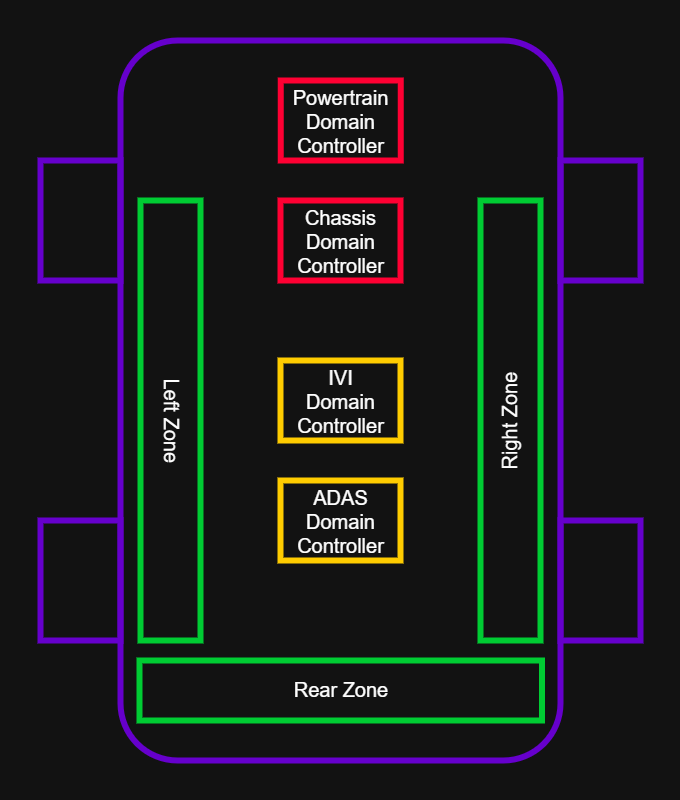

E/E-Architectural schema for a hybrid Zone- and Domain-Concept The picture above shows a schema of a hybrid zonal-domain-architecture that mainly decomposes the body functions into a left a right and a rear zone.

It makes sense to bundle these functions regionally instead of domain related for the subsequent reasons:

- The body functions have homogeneous low bandwidth demands. Edge wiring can be done via LIN, CAN or analog.

- The safety compliance level (Functional Safety) is low (ASIL A or B).

- The synchronization requirements are relatively low, too. If e.g. one door locks 100 ms later than the other, it is no problem.

Using this architectural approach will keep ADAS and IVI in their original domains including all wiring harness for sensors, redundancy and power supply.

Scalability is given by the removal of the rear zone for class A(++) cars. If the Software-Defined-Vehicle (SDV) approach is implemented well, some of the rear-zone-functions like rear-seat-heating can be made accessible via the side zones. Others, like the electric trunk lid lift will not be available at all.

This approach we already see implemented by some US and Chinese OEMs. From our point of view, this architecture will get the industry standard for the next 5 to 10 years.

For more information about how to implement zonal architectures, contact us here.